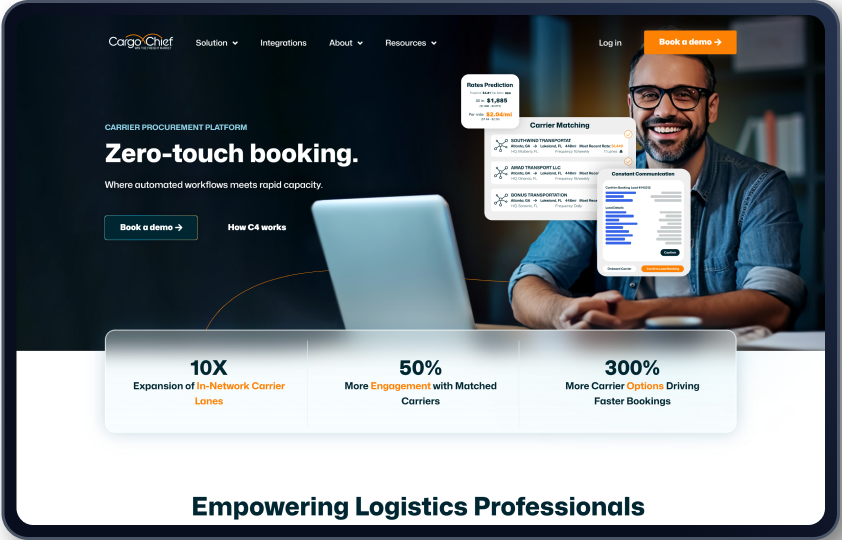

CHALLENGE

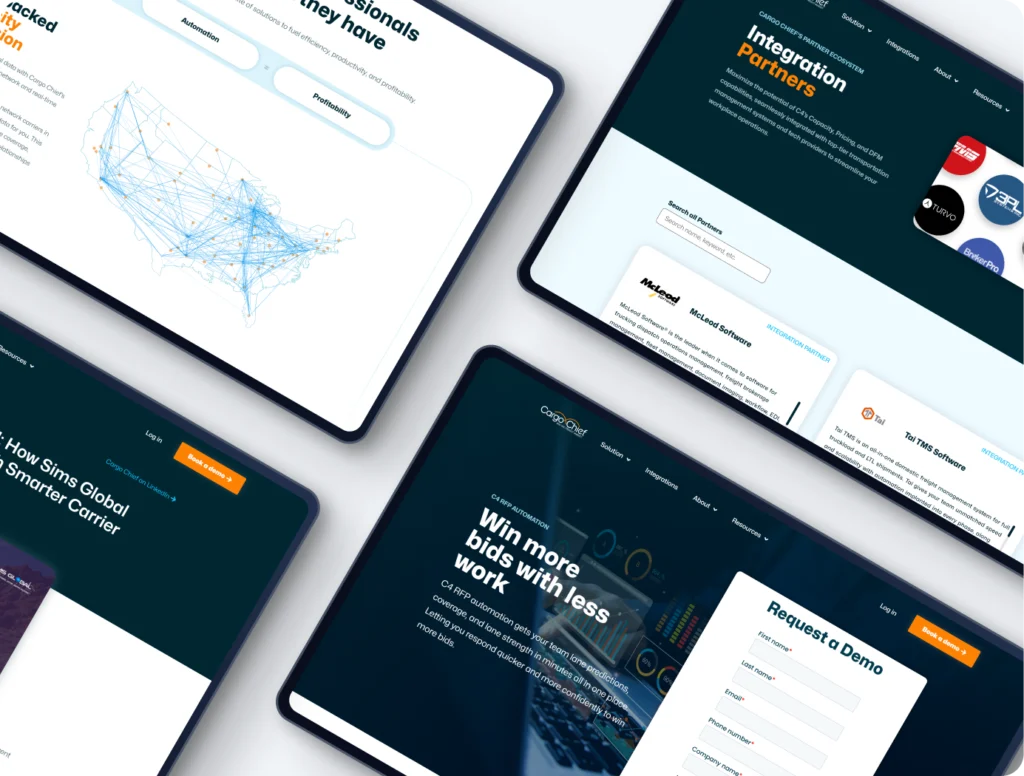

Cargo Chief needed to simplify and speed up how they planned truckloads across several plants. Manual planning, supplier changes, and no real-time updates led to delays and extra costs. Poor forecasting led to overstocking and delivery delays. Their team spent hours recalculating delivery schedules by hand. Mistakes were expensive. They knew it was time to stop firefighting and start improving. So, they brought in Stellar Soft to make it happen.

THE SOLUTION

Stellar Soft rolled up sleeves and got to work to make daily operations smoother without adding extra steps. The result? A custom system that helps Cargo Chief manage production, truck schedules, and deliveries from one easy dashboard. Before, everything had to be double-checked manually. Now, they trust the system to do the heavy lifting:

- Mapped Business Processes – spotted gaps and improved the workflow.

- Custom Load Planning – Calculates delivery options live, updates production, and balances stock.

- Speed Boost – What took hours now takes seconds.

- Fewer Errors – Built-in logic reduced mistakes by 50%.

- Lower Storage Costs – Overstocking dropped, saving 20%.

- Smarter Routes – Shipping costs fell by 20% thanks to optimized planning.

- Loyalty Lift – Customer retention grew 15% after the rollout.

- And the cherry on top? Lead times dropped by 30%, and everything runs smoother than ever.

INTEGRATIONS

To ensure everything ran smoothly, Stellar Soft implemented a set of powerful features. Live production data sync lets truck plans update in real time. Monitoring dashboards with Prometheus and Grafana give complete system visibility. Cloud scaling with Docker and Kubernetes makes it easy to deploy and grow. Google OR-Tools handles the complex math for efficient planning.

KEY PERFORMANCE INDICATORS

The new load planning system helped Cargo Chief work faster, smarter, and with less effort across the board:

- Planning Time – Dropped from hours to seconds with real-time calculations.

- Human Error – Cut in half thanks to smarter logic and automation.

- Storage Costs – Fell by 20% due to better forecasting and inventory control.

- Shipping Costs – Decreased by 20% through optimized route planning.

- Customer Retention – Improved by 15% after smoother, more reliable operations.

- Lead Times – Reduced by 30%, speeding up the entire delivery process.

Our improvements didn’t save time—they made daily operations easier and gave Cargo Chief a competitive edge.